Application scenarios

The lithium battery production processes of code scanning and loading on the tray, hot-pressing formation, high-temperature shelving (or infiltration), room temperature shelving, capacity grading (or aging), OCV/IR, DCIR and hierarchy are included.

System characteristics

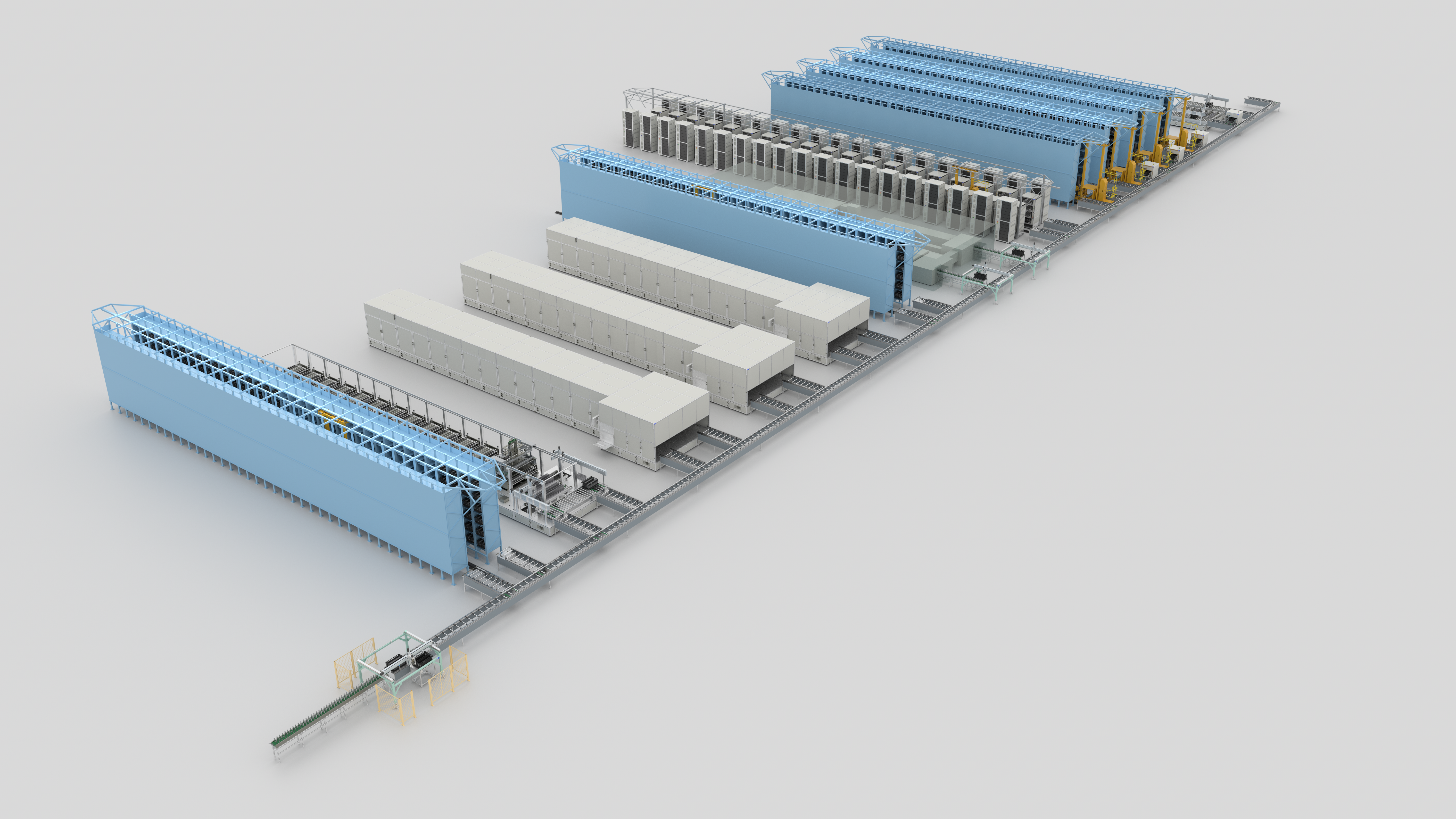

With the tray as carrier, the three-dimensional shelves, lane stacking cranes, exit/entrance working desks, mechanical arms, barcode scanning systems, automatic conveyor systems, MES and WCS systems constitute a complete and closed loop of power battery production automation logistics system.

Functional characteristics

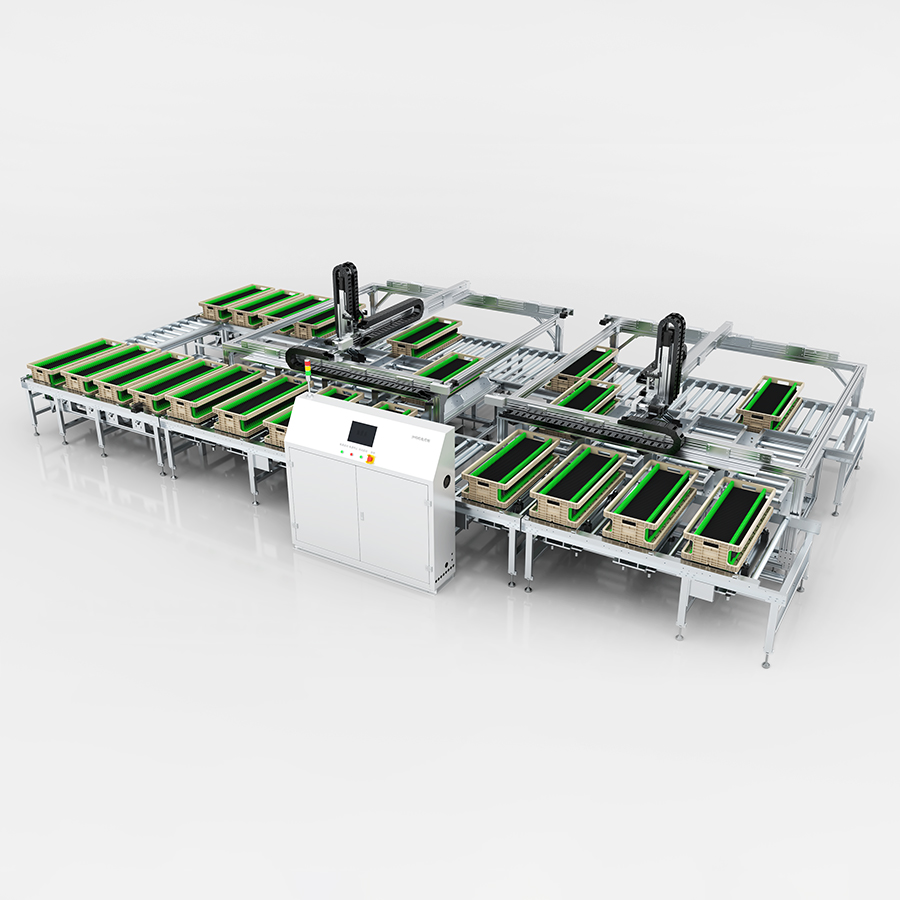

1. The battery formation and capacity-grading system take the tray as carrier, the cells are placed on the tray and flowed to each site for testing. In management, it takes advantage of computer and barcode technology to monitor, track and trace product information in real time which shows the highly integrated system, automation and remarkable production efficiency.

2. It integrates instrumentation, automatizes machinery logistics and manufactures management software to connect all process sites in series into one large system. Through technology management, personnel can achieve on-site unattended production as long as they perform setting operation on the screen. It is suitable for a large number of products with high consistency, with the advantages of saving manpower, improving efficiency and stabilizing production capacity.

|  |  |  |

5V power supply cabinet | High-temperature pressure forming equipment | Capacity-grading press equipment for laminate | OCV testing |

|  |  |  |

| DCIR testing | Pouch battery classification machine | Automated logistics line | Automated warehousing |