Test items

1. Performance test of battery charge and discharge.

2. Cycle life testing of batteries.

3. Self-discharge capacity test of batteries.

System characteristics

1. Positioning mode of the tray: Twice positioning mode is adopted for the tray positioning. First positioning is made to use the guide block around the mechanical unit and the second is the precise positioning of the dowel pins on the diagonal line.

2. Action method: The probe driving mechanism drives the probe module to crimp the cell lug, and the screw rod can be adjusted to change the lug depth crimped by the probe. After detection and crimping are completed, the system will distribute process steps to charge or discharge the batteries automatically.

Functional characteristics

1. Two rows of fans for blowing and cooling are designed under each storage location, with the air blowing evenly from bottom to top, and the thermal homogeneity of storage location is controlled to be no greater than ±2℃. 2 smoke detectors are designed to be installed on the air flue according to the air flue route for each storage location, to monitor and protect the storage position in a real-time way;

2. Probe clamping mechanism: the probe is pressing-type, composed of insulation material and the lug contact pieces, where three contact pieces are current needles, one is for voltage sampling; pressing-type probe pinhead is serrated, gold-plated beryllium copper, with small contact resistance and high current temperature rise less than 10℃, to ensure precision of current passing through and accuracy of voltage sampling; probe module entirely adopts modular design, indicating short time of installation, adjustment and replacement, easy to maintain.

3. Clamping device is compatible with unilateral edge lug and bilateral edge lug, which can realize rapid change of type; meeting customers' personalized requirements.

4. Detecting and judging voltage line or current line bad contact during battery core charging/discharging process, based on original voltage sampling collection battery voltage V1, a voltage V2 on voltage sampling collection power output line is added, which can monitor in the whole process whether the crimping of current and voltage probes is in good condition, in order to completely solve the problem of overcharged or overdischarged phenomenon caused by bad contact of clamping device.

Device parameters

S/N | Content | Specification/Model/Brand |

1 | Cylinder | SMC |

2 | Smoke detector | Weige |

3 | Temperature probe | PT1000 |

4 | Radiator fan | Sunon |

5 | Probe | Yingzhibao |

6 | Tray | PA66+glass fiber |

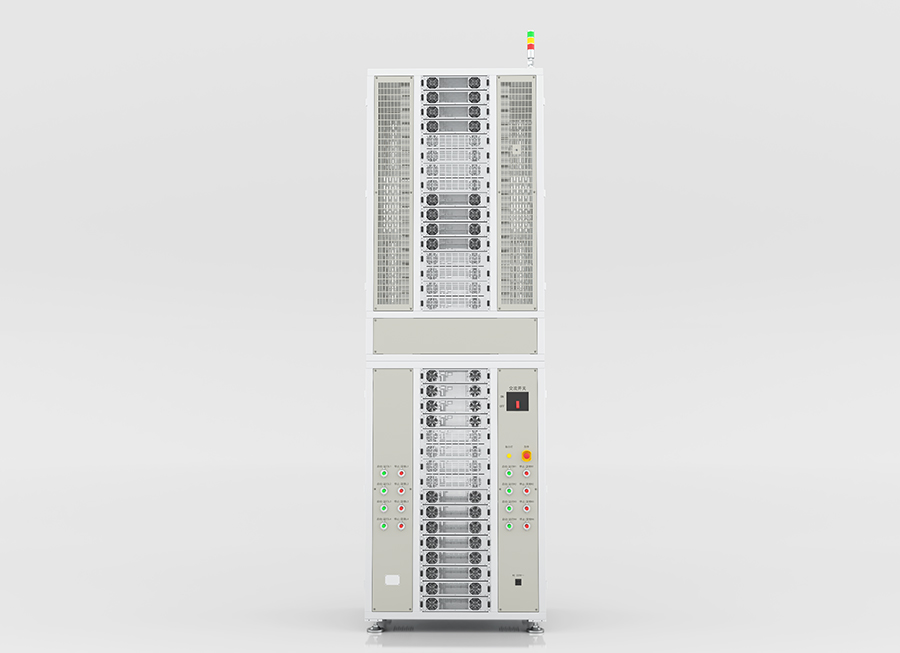

5V power supply cabinet

5V power supply cabinet

HYNN power battery testing system is mainly designed for power battery. Designed with high accuracy, high flexibility and high performance, it can meet all test requirements for battery with the range of 0-5V (Voltage), 20mA-30A-400A (Current).

Model:DECT0530A, DECT0560A, DECT05100A, DECT05200A, DECT05400A

High-temperature pressure forming equipment

High-temperature pressure forming equipment

At present, a heating clamp is used to press the two sides of the battery during the production process of soft package batteries. The gas during the formation can be discharged into the airbag under the pressure, so that the electrolyte can be fully infiltrated and form a good SEI film during the formation of the battery cells.

OCV test equipment for pouch battery

OCV test equipment for pouch battery

HYNN OCV tester can automatically test for the open circuit voltage, AC internal resistance and shell cover insulation (the voltage between the positive electrode and shell) of the single cell in the battery tray. OCV testing is the essential process of battery manufacturing. Combining battery testing with battery tray for batch testing or single testing, it can reach to fast and reliable testing results. The production management and control system automatically calculates the K value according to the test data, and automatically completes the binding of the production data information, automatic saving and binding information. Data can be export through internet connection.

DCIR tester for pouch battery

DCIR tester for pouch battery

Through the integration of PC computer, PLC and hardware, HYNN DCIR tester can accurately measure the DC internal resistance and open circuit voltage, realizing the perfect combination with the automation. The DCIR tester can not only test for the important parameters of battery measurement, but also fulfill the development of industrial automation and technology.

Pouch battery classification machine

Pouch battery classification machine

HYNN battery level grading machine automatically scans barcode for the incoming battery, selecting and grading finished batteries according to some set rules. The user can set rules and numbers of levels for grading. Programming is proceed via data of battery manufacturing process. The formation management control system can automatically grade and upload grading results data according to data from former process. The grading machine can perfectly connect with the automatic logistics equipment and process equipment.