Test items

1. Battery cell forming performance test.

2. Battery cell temperature acquisition, monitoring test.

3. Battery cell compression stressed test.

Functional characteristics

1. During hot pressing, the battery is heated to increase the fluidity of the electrolyte, so that the viscosity of the electrolyte is high, and the electrolyte is fully infiltrated, easy to form a dense SEI film, in favor of extending the cycle life of the cell. The battery cell is rapidly cooled and shaped into formation by cold pressing, which can control the shape of the battery cell. This type of hot-pressed battery cell has the advantages of good active material performance, low probability of bump, long cycle life and so on.

2. For the horizontal hot pressing mode, the servo screw option is adopted for the clamp, indicating uniform pressure transmission, with the pressure control error ≤10kgf.

3. Heating press fixture adopts electric heating method, with the temperature to be flexibly adjusted according to the actual condition. The maximum design temperature is 90℃.

4. The fixture is compatible with both unilateral lug and bilateral lug type, capable of quick change, able to meet the clients' personalized customized demand.

Equipment parameters

S/N | Content | Parameter |

1 | Voltage measurement range | 0~5V for charge, 1.5~5V for discharge, resolution ratio of 0.1mV |

2 | Current measurement range | 20mA~60A, resolution ratio of 0.1mA |

3 | Current and voltage accuracy | ±(0.05%RD+0.05%FS) |

4 | Pressure uniformity between laminates | ≤100kgf |

5 | Pressure control accuracy | ≤20kgf |

6 | Temperature uniformity of each battery cell | ≤2℃ |

7 | Communication method | Ethernet |

8 | Channel utilization | ≥99.9% |

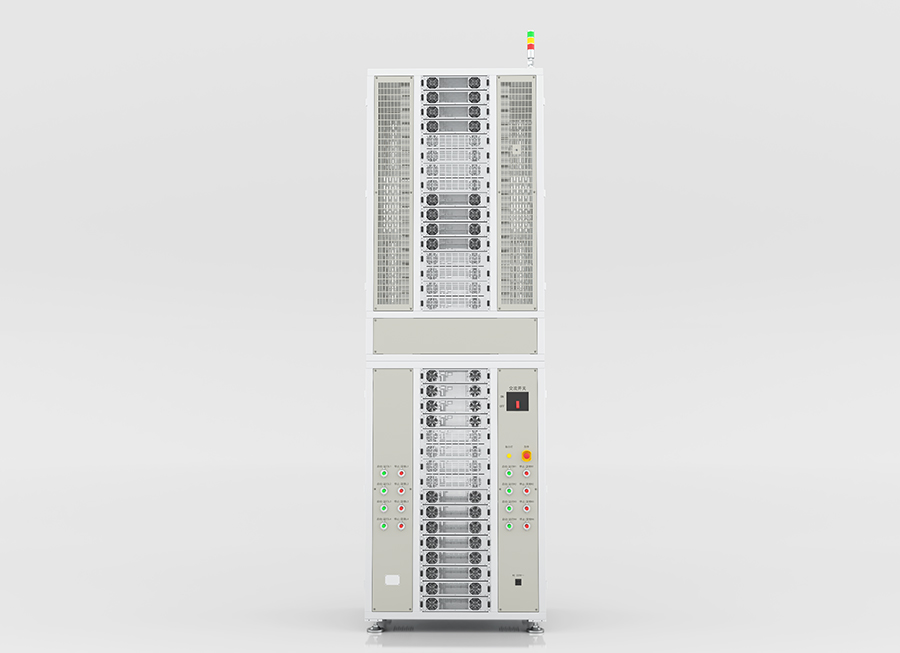

5V power supply cabinet

5V power supply cabinet

HYNN power battery testing system is mainly designed for power battery. Designed with high accuracy, high flexibility and high performance, it can meet all test requirements for battery with the range of 0-5V (Voltage), 20mA-30A-400A (Current).

Model:DECT0530A, DECT0560A, DECT05100A, DECT05200A, DECT05400A

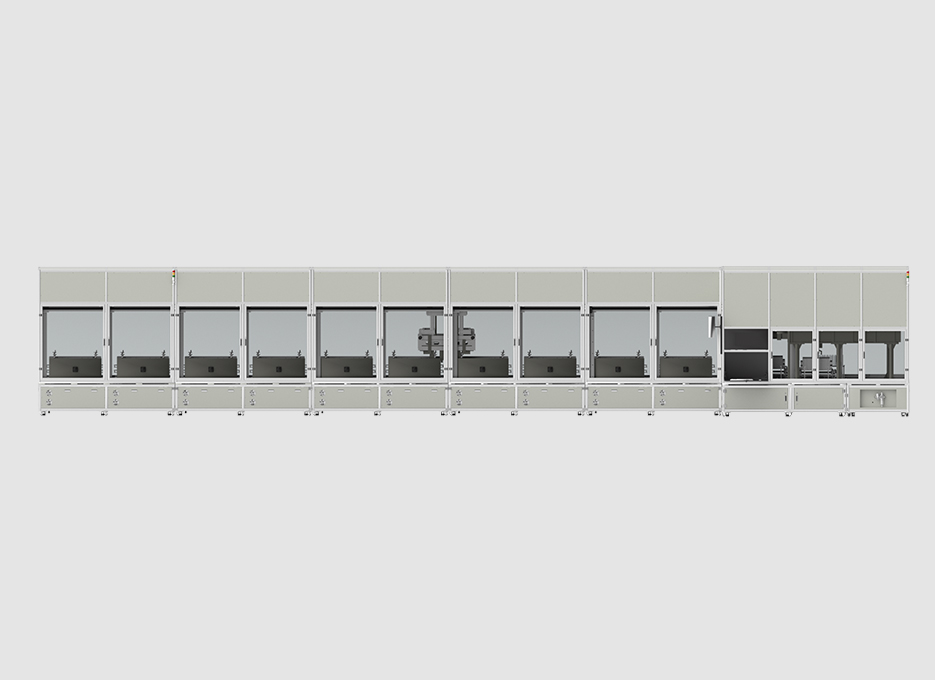

Capacity-grading press equipment

Capacity-grading press equipment

HYNN press machine can complete the once-off crimping test for the entire battery panel and improve production efficiency. After the test is completed, it can automatically cut off the work step process, upload the test data and connect with the front and back processes seamlessly to realize data interaction.

OCV test equipment for pouch battery

OCV test equipment for pouch battery

HYNN OCV tester can automatically test for the open circuit voltage, AC internal resistance and shell cover insulation (the voltage between the positive electrode and shell) of the single cell in the battery tray. OCV testing is the essential process of battery manufacturing. Combining battery testing with battery tray for batch testing or single testing, it can reach to fast and reliable testing results. The production management and control system automatically calculates the K value according to the test data, and automatically completes the binding of the production data information, automatic saving and binding information. Data can be export through internet connection.

DCIR tester for pouch battery

DCIR tester for pouch battery

Through the integration of PC computer, PLC and hardware, HYNN DCIR tester can accurately measure the DC internal resistance and open circuit voltage, realizing the perfect combination with the automation. The DCIR tester can not only test for the important parameters of battery measurement, but also fulfill the development of industrial automation and technology.

Pouch battery classification machine

Pouch battery classification machine

HYNN battery level grading machine automatically scans barcode for the incoming battery, selecting and grading finished batteries according to some set rules. The user can set rules and numbers of levels for grading. Programming is proceed via data of battery manufacturing process. The formation management control system can automatically grade and upload grading results data according to data from former process. The grading machine can perfectly connect with the automatic logistics equipment and process equipment.

.jpg)