System characteristics

The automated three-dimensional warehouse system consists of three-dimensional warehouse, high-rise shelf warehouse, automatic access system, materials haulage equipment, control and management equipment, and civil utilities, etc. It is the collective creation of high technologies in modern logistics industry, integrating machinery, electricity, software, communication and information with multiple sets of different mechanical devices being interconnected inside, thus achieving the intelligent effect under the control of electricity and software.

Application items

1. Standing process for batteries under normal or high temperature.

2. Formation and capacity-grading testing procedure.

Functional characteristics

1. Saving the space of the warehouse and fully utilizing the vertical space of the warehouse.

2. Three-dimensional warehouse forms an advanced production chain and promotes development of productivity.

3. On one hand, fully mechanization and automation of the warehouse processes can economize manpower and reduce labor costs, on the other hand, can improve working efficiency greatly.

4. Warehousing management relying on computer can easily achieves "first-in first-out", prevent the cargo from aging, deterioration and rust and avoid cargo loss.

5. Centralized cargo allocation is easy for control and management. Especially, the use of electronic computer not only achieves the automatic control of operations, but also enables information processing.

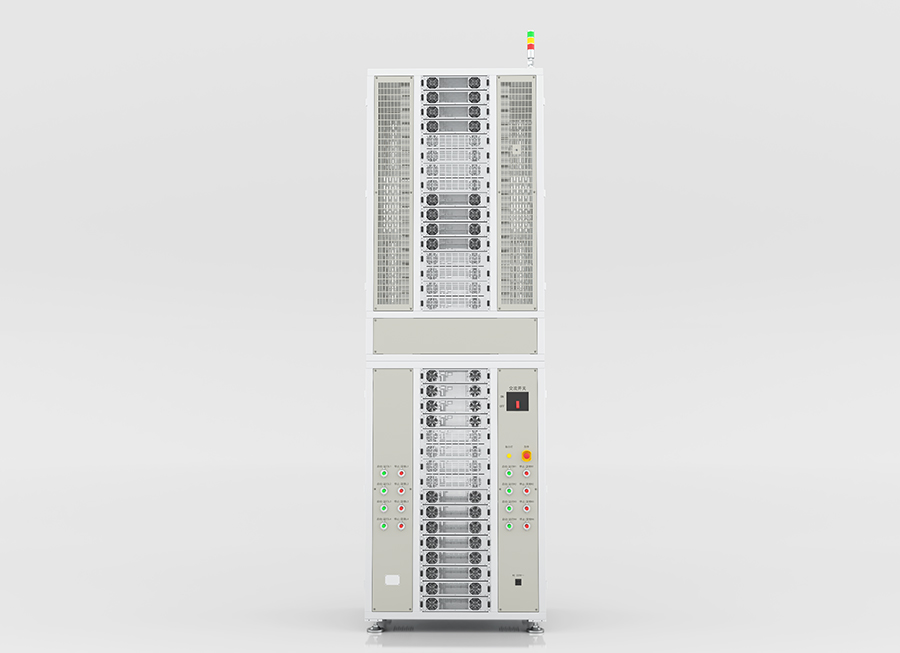

5V power supply cabinet

5V power supply cabinet

HYNN power battery testing system is mainly designed for power battery. Designed with high accuracy, high flexibility and high performance, it can meet all test requirements for battery with the range of 0-5V (Voltage), 20mA-30A-400A (Current).

Model:DECT0530A, DECT0560A, DECT05100A, DECT05200A, DECT05400A

High-temperature pressure forming equipment

High-temperature pressure forming equipment

At present, a heating clamp is used to press the two sides of the battery during the production process of soft package batteries. The gas during the formation can be discharged into the airbag under the pressure, so that the electrolyte can be fully infiltrated and form a good SEI film during the formation of the battery cells.

Capacity-grading press equipment

Capacity-grading press equipment

HYNN press machine can complete the once-off crimping test for the entire battery panel and improve production efficiency. After the test is completed, it can automatically cut off the work step process, upload the test data and connect with the front and back processes seamlessly to realize data interaction.

OCV test equipment for pouch battery

OCV test equipment for pouch battery

HYNN OCV tester can automatically test for the open circuit voltage, AC internal resistance and shell cover insulation (the voltage between the positive electrode and shell) of the single cell in the battery tray. OCV testing is the essential process of battery manufacturing. Combining battery testing with battery tray for batch testing or single testing, it can reach to fast and reliable testing results. The production management and control system automatically calculates the K value according to the test data, and automatically completes the binding of the production data information, automatic saving and binding information. Data can be export through internet connection.

DCIR tester for pouch battery

DCIR tester for pouch battery

Through the integration of PC computer, PLC and hardware, HYNN DCIR tester can accurately measure the DC internal resistance and open circuit voltage, realizing the perfect combination with the automation. The DCIR tester can not only test for the important parameters of battery measurement, but also fulfill the development of industrial automation and technology.