Characteristics

1. The energy of the whole system has two-way flow and can automatically adjust the energy direction. That is, when charging, the energy can flow from the three-phase grid to the battery pack, while discharging, the energy is fed back from the battery pack to the three-phase grid.

2. The status of each channel of the system, including voltage, current, and working status etc., will be sent to the server in real time.

3. One certain or more channels can be set as the "equalization channel". After being set as the equalization channel, it will accept the control of the server and automatically perform the charging and discharging actions. After the channel receives the stop operation, it will exit the equalization mode.

4. The equalization channel will always run "working condition simulation" working step. As working condition of working steps is adjusting to charging and discharging in real time, the channel will start working condition of working steps and enter operation status when the equalization channel is set. At this time, the equipment battery should be connected well.

5. The charging and discharging system discovers the server at startup. After the connection is successful, the connection information is cached in the system to provide the next use and free of configuration.

Basic structure of the system

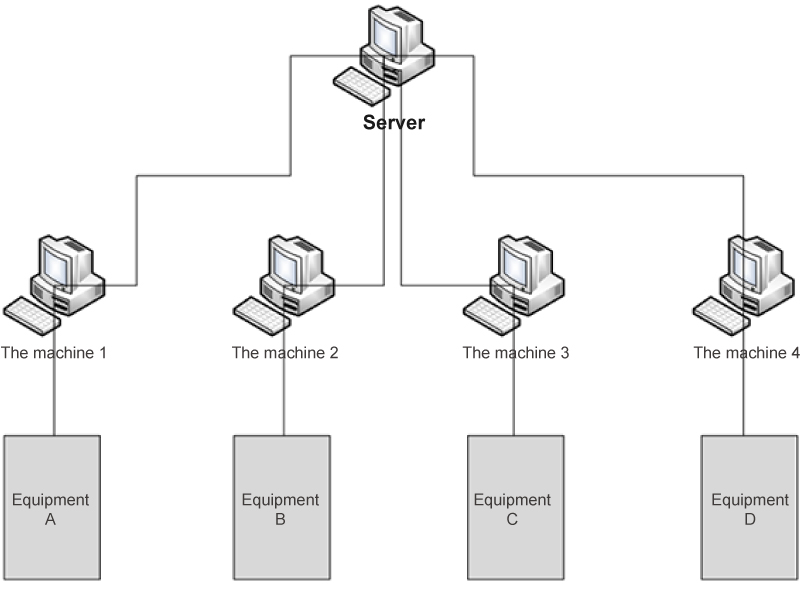

A. On the basis of the original charging and discharging system, the whole system sets the server side to control all the situations. The server side and charging and discharging system are communicating through the network.

B. The server side monitors the power status of each charging and discharging system in real time and controls the controlled machine to perform power equalization to change the charging or discharging power of the channel in real time, so that the total charging and discharging power of the entire system tends to zero.

C. The server has a certain delay in the control of power, preventing the power from constantly shaking, and the delay is about 10~20 seconds.

D. The server and charging and discharging system can be deployed in the same computer or different computers in the same LAN.

Equipment parameters

S/N | Parameter Content | Low Voltage Type | Regular Type | High Voltage Type |

60~120V | 150~800V | 850~1,500V | ||

1 | AC power input voltage | 380VAC±10% three-phase and five-wire system, frequency 50Hz±5Hz | ||

2 | AC power input power | Max≤120KW | Max≤350KW | |

Actual power is based on equipment model | ||||

3 | Power factor | >0.99 (rated power) | ||

4 | Efficiency | >92% (rated power) | ||

5 | Energy feedback | Current THD<5%, power>rated power 50%,feedback efficiency>85% | ||

6 | Current rising/falling response time | 10ms | ||

7 | Charging and discharging switch time | 30ms | ||

8 | Output DC voltage accuracy | ± (0.05%FS+0.05%RD) | ||

9 | Output DC voltage accuracy | ± (0.05%FS+0.05%RD) | ||

10 | Output DC current range | Dual channel each ±400A | Dual channel each ±300A | Dual channel each ±200A |

Parallel connection to ±800A | Parallel connection to ±600A | Parallel connection to ±400A | ||

11 | Main channel data acquisition cycle | 10ms | ||

12 | Upper computer data record cycle | Fastest speed of 10ms, recording cycle can be set by software | ||

Notebook digital battery test system

Notebook digital battery test system

HYNN high precision battery testing system is mainly designed for notebook and digital product lithium battery pack. With high power, high precision and high performance, it can meet to all ability test requirements for notebook and digital product battery pack with the range of 0-20V (Voltage), 0-10A (Current).

Model:NT0505C, NT01005C, NT01010C, NT02005C, NT02010C

Power battery test system

Power battery test system

The energy saving test system for power battery pack independently developed by Shenzhen HYNN Technology Co., Ltd. can carry out charging and discharging test of working condition to packed power battery system, detect capacity, efficiency, charging status, heat properties and other comprehensive properties of the battery pack, verify detection precision and accuracy of energy status of the battery management system, and provide reliable basis for effective management after the battery pack is assembled on vehicles.

EOL test system

EOL test system

Current battery module and pack testing process is lowly automated, and the record analysis is in poor capabilities. Aimed at these problems, HYNN proposed a fully intelligent tester, EOL test system. The system integrates insulation testing, BMS calibration, OCV testing and other functions to achieve the entire workflow fully intelligent and automated, in order to reduce labor cost and improve efficiency.

Balanced charge and discharge test system

Balanced charge and discharge test system

HYNN battery charging and discharging testing system is mainly designed for lithium battery cell balance. The equipment can test single battery cell for independent charging-discharging, as well as the pack balance performance. The channel is in modular design: channel number can be change flexibly according to battery string number; Overall channels are stackable; The series circuit is kept on when charging. Designed with high efficiency, high accuracy and high performance, it can meet all test requirements for battery pack battery charging and discharging testing.