1. The energy of the whole system has two-way flow and can automatically adjust the energy direction. That is, when charging, the energy can flow from the three-phase grid to the battery pack, while discharging, the energy is fed back from the battery pack to the three-phase grid.

2. The DCAC module uses space vector adjusting technology and digital control to have a high voltage utilization ratio and less current harmonics distribution.

3. The energy storage module can realize internal conversion of dual channel charging and discharging energy; if the charging and discharging energy between two channels are equal, the efficiency of energy conversion between two channels can reach 99%.

4. Fast conversion of output current and non-overshoot of current can avoid impact of equipment to the battery pack.

5. The CAN2.0 interface can access battery package BMS data and control the battery package status in real time during the charging and discharging process.

6. Capable of communicating with PACK production line, such as OPC, Internet and other interface protocols.

Test items

1. Charging mode: CC-CV constant current and constant voltage, CC constant current, CV constant volgate, constant power.

2. Charging cut-off condition: Total voltage, current, time, capacity, temperature, single viltage, SOC, etc.

3. Discharging mode: Constant current, constant power, linear discharging, pulse discharging, constant resistance discharging, simulation of working condition.

4. Discharge cut-off condition: Total voltage, current, time, capacity, temperature, single viltage, SOC, etc.

5. DCIR: Supporting DCIR test, capable of setting test conditions conveniently through upper computer.

6. Working condition simulation: Supported.

Equipment parameters

S/N | Parameter Content | Low Voltage Type | Regular Type | High Voltage Type |

60~120V | 150~800V | 850~1,500V | ||

1 | AC power input voltage | 380VAC±10% three-phase and five-wire system, frequency 50Hz±5Hz | ||

2 | AC power input power | Max≤120KW | Max≤350KW | |

Actual power is based on equipment model | ||||

3 | Power factor | >0.99 (rated power) | ||

4 | Efficiency | >92% (rated power) | ||

5 | Energy feedback | Current harmonics THD<3%, feedback efficiency>92% | ||

6 | Current rising/falling response time | 10ms | ||

7 | Charging and discharging switch time | 30ms | ||

8 | Output DC voltage accuracy | ± (0.05%FS+0.05%RD) | ||

9 | Output DC voltage accuracy | ± (0.05%FS+0.05%RD) | ||

10 | Output DC current range | Dual channel each ±400A | Dual channel each ±300A | Dual channel each ±200A |

Parallel connection to ±800A | Parallel connection to ±600A | Parallel connection to ±400A | ||

11 | Main channel data acquisition cycle | 10ms | ||

12 | Upper computer data record cycle | Fastest speed of 10ms, recording cycle can be set by software | ||

Notebook digital battery test system

Notebook digital battery test system

HYNN high precision battery testing system is mainly designed for notebook and digital product lithium battery pack. With high power, high precision and high performance, it can meet to all ability test requirements for notebook and digital product battery pack with the range of 0-20V (Voltage), 0-10A (Current).

Model:NT0505C, NT01005C, NT01010C, NT02005C, NT02010C

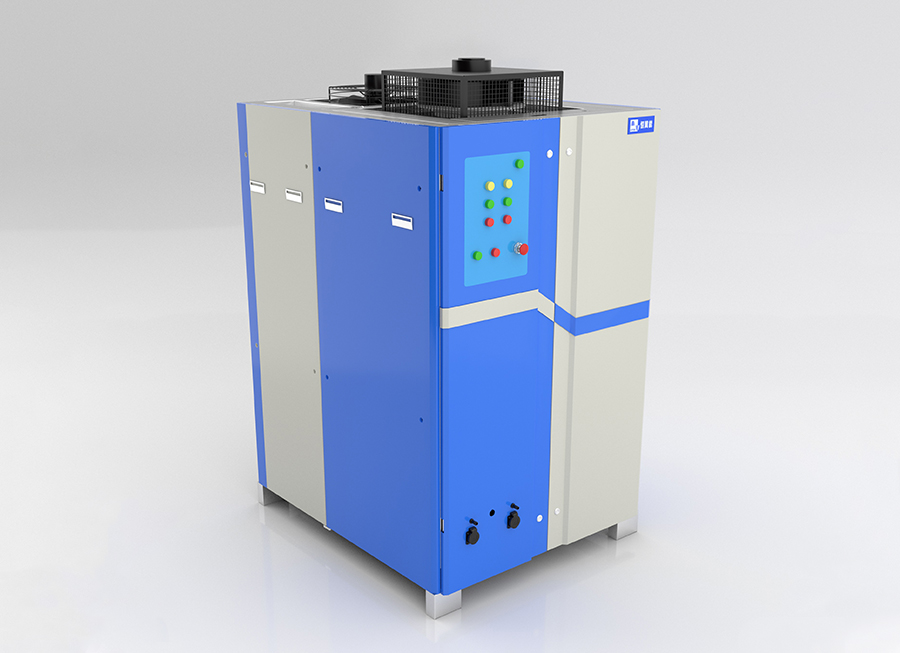

Electric vehicles and energy storage test system

Electric vehicles and energy storage test system

The design of electric vehicles and energy storage system meets the needs of saving energy and reducing production costs during the battery production process by balancing the total loop power to make the utilization of battery power more efficient.

EOL test system

EOL test system

Current battery module and pack testing process is lowly automated, and the record analysis is in poor capabilities. Aimed at these problems, HYNN proposed a fully intelligent tester, EOL test system. The system integrates insulation testing, BMS calibration, OCV testing and other functions to achieve the entire workflow fully intelligent and automated, in order to reduce labor cost and improve efficiency.

Balanced charge and discharge test system

Balanced charge and discharge test system

HYNN battery charging and discharging testing system is mainly designed for lithium battery cell balance. The equipment can test single battery cell for independent charging-discharging, as well as the pack balance performance. The channel is in modular design: channel number can be change flexibly according to battery string number; Overall channels are stackable; The series circuit is kept on when charging. Designed with high efficiency, high accuracy and high performance, it can meet all test requirements for battery pack battery charging and discharging testing.